What do you think about the iPhone x dual battery design?

What do you think about the iPhone x dual battery design?

1. The battery that has been in contact with all kinds of special models, including the iPhoneX, is not strictly used until the model is applied to the iPhone X.

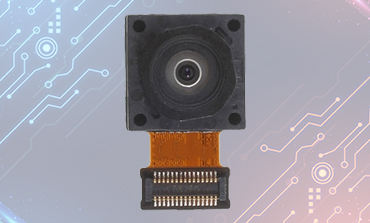

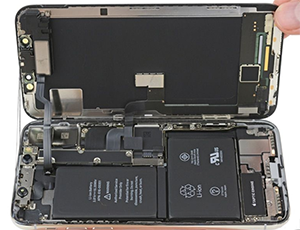

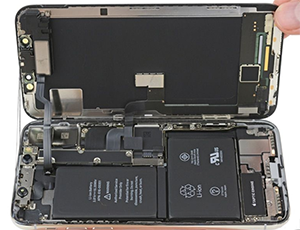

2. According to my analysis, the use of L-type batteries in iPhoneX is mainly based on the reasonable layout of the internal motherboard, memory, telephone card, camera, speaker, and other accessories.

3. Some mobile phones used square or rectangular in the early days. The motherboard and battery interface, and other series of cable layouts are too dense and too long, which will increase the resistance of a certain total circuit. A certain energy loss of the battery is caused during the transmission. Of course, the resistance of the pure copper cable circuit board is very low, and the length will always increase the resistance. With the design concept of the iPhone, I will definitely consider these.

4. Of course, the L-type battery is optimized for the internal space layout. Why are other mobile phone providers not following up? The problem is here, the design cost of the shaped battery pack is much younger than the square battery technology research and development experience. Personally, the 90% soft pack battery manufacturer's production equipment does not have the (batch) production of the special type battery (multiple models). ability. The process involved, the packaging equipment, the mold too much, and the cutting of the positive and negative sheets are too much waste. Moreover, many packaging equipments only target the production capacity of a special-shaped equipment. If the shape of the battery-shaped profile is changed, the equipment must be greatly modified. How much does it cost to exchange an order for a battery? Labor costs have also doubled compared to prismatic batteries.

5. Why does iPhoneX use dual battery combined parallel (two squares) instead of integrated L-type battery? It may be because of the capacity of mass production, many battery factories can produce special-shaped batteries, but 95% semi-automatic plus manual, low efficiency . What the iPhone is currently demanding from various suppliers is that the assembly line is fully automated, but wherever there is a need for labor, there is an urgent need to eliminate it. Manually shaped batteries are not suitable for current investment (causing bad uncontrollable factors). But there is an urgent need to change the status quo. First of all, to get a certain model for strong research and development of certain models.

6. So far unknown how to achieve, the overall L-type battery seal up to five sides, L-angle position sealing technology is difficult, L-shaped internal positive and negative pieces can not be square winding, the internal diaphragm can not use the traditional stack Square battery mode and winding mode. The square battery has only 3 side seals. The gap is here.

If you need more iPhone repair parts, please Contact Jack Telecom www.jacktelecom.com

1. The battery that has been in contact with all kinds of special models, including the iPhoneX, is not strictly used until the model is applied to the iPhone X.

2. According to my analysis, the use of L-type batteries in iPhoneX is mainly based on the reasonable layout of the internal motherboard, memory, telephone card, camera, speaker, and other accessories.

3. Some mobile phones used square or rectangular in the early days. The motherboard and battery interface, and other series of cable layouts are too dense and too long, which will increase the resistance of a certain total circuit. A certain energy loss of the battery is caused during the transmission. Of course, the resistance of the pure copper cable circuit board is very low, and the length will always increase the resistance. With the design concept of the iPhone, I will definitely consider these.

4. Of course, the L-type battery is optimized for the internal space layout. Why are other mobile phone providers not following up? The problem is here, the design cost of the shaped battery pack is much younger than the square battery technology research and development experience. Personally, the 90% soft pack battery manufacturer's production equipment does not have the (batch) production of the special type battery (multiple models). ability. The process involved, the packaging equipment, the mold too much, and the cutting of the positive and negative sheets are too much waste. Moreover, many packaging equipments only target the production capacity of a special-shaped equipment. If the shape of the battery-shaped profile is changed, the equipment must be greatly modified. How much does it cost to exchange an order for a battery? Labor costs have also doubled compared to prismatic batteries.

5. Why does iPhoneX use dual battery combined parallel (two squares) instead of integrated L-type battery? It may be because of the capacity of mass production, many battery factories can produce special-shaped batteries, but 95% semi-automatic plus manual, low efficiency . What the iPhone is currently demanding from various suppliers is that the assembly line is fully automated, but wherever there is a need for labor, there is an urgent need to eliminate it. Manually shaped batteries are not suitable for current investment (causing bad uncontrollable factors). But there is an urgent need to change the status quo. First of all, to get a certain model for strong research and development of certain models.

6. So far unknown how to achieve, the overall L-type battery seal up to five sides, L-angle position sealing technology is difficult, L-shaped internal positive and negative pieces can not be square winding, the internal diaphragm can not use the traditional stack Square battery mode and winding mode. The square battery has only 3 side seals. The gap is here.

If you need more iPhone repair parts, please Contact Jack Telecom www.jacktelecom.com